Engineering

AMEL provides value-added services to compliment the core manufacturing production. We are able to step in anytime during the design process to help develop, refine and even help market the product for you.

We provide an end to end design service of which you can choose the full process, or individual steps, to meet your specific needs. This means, the whole design, engineering and manufacturing process happens seamlessly, under one roof with team members from different departments working closely together to ensure optimum results. Services include Computer Aided Design (CAD), Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), Reverse Engineering and Rapid Prototyping.

Computer Aided Design (CAD)

Computer-Aided Design (CAD) revolutionizes product development by enabling engineers and architects to create precise digital models of objects or structures. Using specialized software, CAD facilitates efficient drafting, design iteration, and analysis. It enhances collaboration, reduces errors, and accelerates the overall design process, spanning industries from architecture to manufacturing.

• Component 3D Modelling Accurate representation of the size, structure and materials of components in 3D CAD.

• Assembly 3d Modelling Accurate representation of combined components assembled in 3D CAD.

• 3D Rendering and Lighting Product visuals with realistic surfaces, sub-surfaces, reflections, specular diffusion, transparency, colours, materials and textures, with lighting, shadowing and illumination.

• 2D Conversion to 3D CAD CAD Modelling converted from accurate 2D drawing sheets, creating a 3D Version. CAD Models can also me developed from sketches and concepts provided by, and working alongside, the customer.

• Scanning and Reverse Engineering 3D CAD Models can be created from 3D Scanned mesh data of existing objects.

• Mesh Model to CAD Conversion 3d Mesh models can be recreated/converted into CAD models.

• Sheet Metal Design Objects can be designed to me made out made from flat sheet metal with bend process and assembly data.

• Material Properties and Analysis CAD Models can be analysed with various materials for accurate production predictions, including area, mass, volume, density, ultimate strength, thermal conductivity and more.

• Drafting for Manufacturing 2D Production drawings to aid the manufacturing process, catered to the product to show all key details.

• Site Layouts 3D representation of site layouts to show scale, placement and available space.

Computational Fluid Dynamics (CFD)

AMEL provides a CFD consultancy with a vast knowledge of fluid dynamics, and can help you: evaluate, validate and optimise your system's performance, reduce product development time and testing costs, test product performance prior to production.

CFD also referred to as flow simulation, is a computer simulation technique that allows detailed analysis of fluid flow through any product. It allows the fluid mass flow, velocity, density, temperature, pressure, concentration or any derived fluid property to be calculated at all locations within the flow field. The interaction of the fluid with its solid boundaries, such as fluid-dynamic forces and heat transfer rates can also be calculated accurately for use in stress analysis.

By using CFD techniques, you will be able to verify if your product will conform to a client's specifications, which greatly improves the product development process. CFD can be used to: calculate design mass flow rates, pressure drops and heat transfer rates together with fluid dynamic forces - lift, drag and pitching moments.

With the latest developments in CFD analysis, it is now easy to embed CFD into the design process at an early stage. As soon as a CAD model or 3D visualisation model is reasonably realistic, CFD analysis can be conducted to check for flow or thermal issues. This means that the design can be changed and optimised very early on, saving time and money.

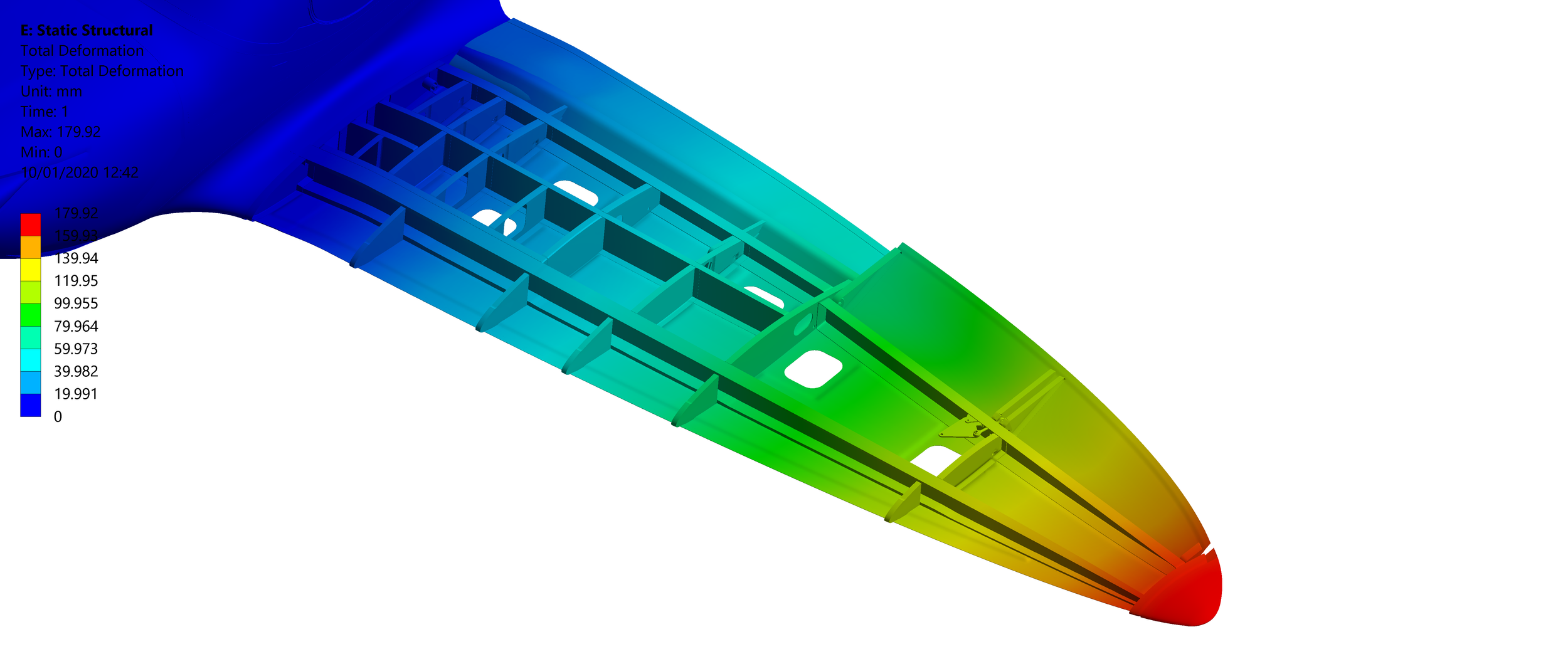

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a computer based engineering solution used to solve complicated engineering issues. It is a computer model of a design or material that is stressed and analysed providing an accurate, reliable solution which is far more cost effective, convenient and speed efficient that traditional closed-form analysis techniques. FEA can be used for new product or refinement of an existing product and is fast becoming an industry standard.

AMEL will help you to verify if a proposed design for will be able to perform to the required specifications prior to manufacturing or construction, while helping to determine any required design modifications. We provide a range of FEA solutions including structural, vibration, seismic, thermal and non-linear.

The benefits of FEA include:

Assess performance and safety of any design prior to manufacture

Identify and resolve design faults at an early stage of the design process

Optimise product performance

Minimise cost of testing and materials

Speed up time to market

Reverse Engineering

By use of these techniques, in combination with either laser scanning or photogrammetry, we can also reverse engineer existing components for further enhancement or simply to provide an alternative source of replacement parts.

Many existing products have been crafted by eye without reference to engineering drawings. However, modifying these products to meet the standards and quality required by today’s market may prove difficult without such information. In these circumstances Reverse Engineering is a technique that can be employed to gather the required data.

AMEL the skills and tools, including laser scanning and photogrammetry, to provide the solution you need.